Across the United States and Canada electrical hazards affect almost every industry. From hot noisy construction sites to modern office towers the risk of shock fire and equipment failure is always present.

Both countries are known for strict safety rules and detailed standards. Even so electrical incidents still happen which shows how important it is to stay alert and keep systems up to date.

The Rules: Electrical Safety Regulations

In North America electrical safety is built on strong national codes.

In the United States the National Electrical Code (NEC) sets the basic rules for homes businesses and industry

In Canada the Canadian Electrical Code (CEC) does the same job

On top of these codes

OSHA in the United States

CSA and local regulators in Canada issue standards and guidance to protect workers.

These rules are updated regularly as technology changes and as investigators learn lessons from past incidents. The goal is simple: clear practical requirements that reduce electrical risk in real workplaces.

Common Electrical Hazards

Even with strong rules the same types of hazards appear again and again.

Old or damaged wiring

In older buildings wiring hidden in walls and ceilings can be worn cracked or overloadedOverloaded circuits

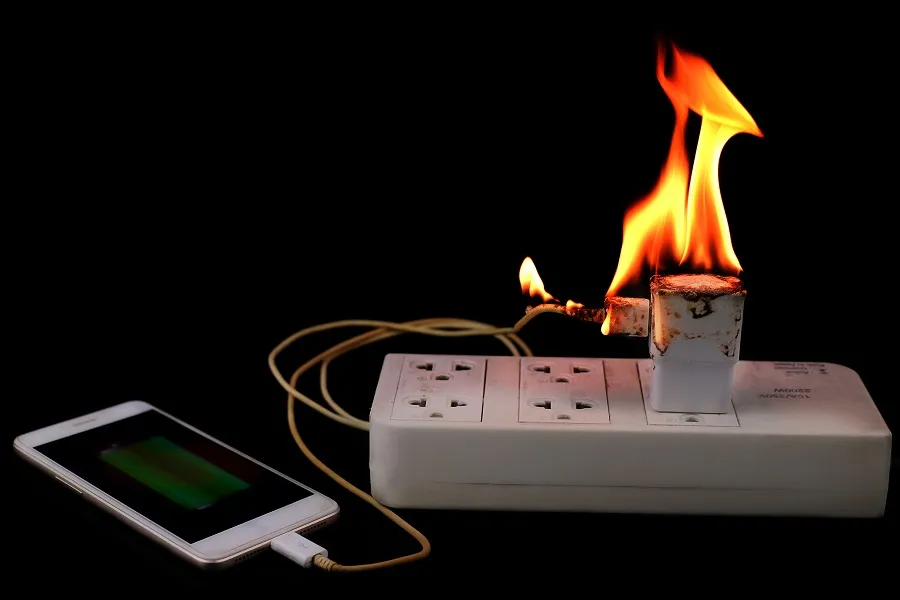

Offices full of computers screens printers and chargers can push circuits beyond their design limitsMisused extension leads and power boards

Daisy chaining power boards or running cords under carpets creates heat trip hazards and fire riskWater and electricity together

Kitchens workshops outdoor areas and cleaning operations all increase the chance that equipment will get wetPoor maintenance

Loose connections broken outlets and damaged cords that are not repaired in time can turn a small fault into a serious incident

Regular inspections and preventative maintenance are key. They allow teams to fix problems while they are still small and cheap to resolve.

Learning From Incidents

History in both the United States and Canada contains many examples of electrical accidents.

Fires that start in crowded workshops or storage rooms

Workers who receive serious shocks while using faulty tools

Equipment failures that shut down critical operations

Behind every incident there are people, families and often clear warning signs that were missed.

These events remind us that checklists and codes are only useful if they are followed in daily work.

Preventing Electrical Incidents

Good electrical safety starts long before someone gets hurt.

Key steps include

Formal risk assessments

Walk the site identify where electricity is used and decide what controls are neededClear procedures

Lockout and tagout, isolation of circuits, permit to work systems for live or high risk jobsTraining as part of onboarding

New staff learn how to use equipment safely and how to report problems from their first dayPersonal protective equipment (PPE)

Insulated gloves, eye protection and arc rated clothing where required

New technology also helps.

Modern circuit breakers can detect faults faster

Ground fault circuit interrupters (GFCIs) reduce shock risk in wet or outdoor areas

When companies combine good design, modern protection devices and solid work practices they build a strong barrier against electrical harm.

People and Safety Culture

At the heart of electrical safety are the people on site.

The worker who decides to stop and report a hot outlet

The electrician who refuses to bypass a safety device

The supervisor who supports safe choices even when the job is running late

Effective training programs teach staff how to spot hazards and what to do about them. Over time the goal is to build a culture where everyone feels responsible for safety not only for themselves but for their workmates too.

This culture is not created by policies alone. It grows when managers lead by example, listen to concerns and act quickly when someone raises a risk.

Being Ready for Emergencies

Even with strong controls things can still go wrong. That is why emergency planning is essential.

Good preparation includes

Accessible first aid kits and fire extinguishers

Staff trained to use them safely

Clear evacuation routes and assembly points

Up to date emergency contact lists

Regular drills so people know what to do under pressure

When an incident happens calm and practised responses can reduce injuries and limit damage.

Moving From Rules to Real Safety

Electrical hazards in US and Canadian workplaces are complex but they can be managed. Regulations like the NEC and CEC provide the base. Real safety however depends on how employers and workers use those rules day to day.

Everyone has a role

Electricians who design and maintain safe systems

Supervisors who plan work and enforce safe methods

Front line workers who follow procedures and speak up about hazards

Company leaders who fund maintenance and training instead of delaying it

The aim is clear and simple: every worker goes home safe at the end of the day without being harmed by electricity. Achieving this depends on practical controls, steady attention and a shared commitment to continuous improvement.